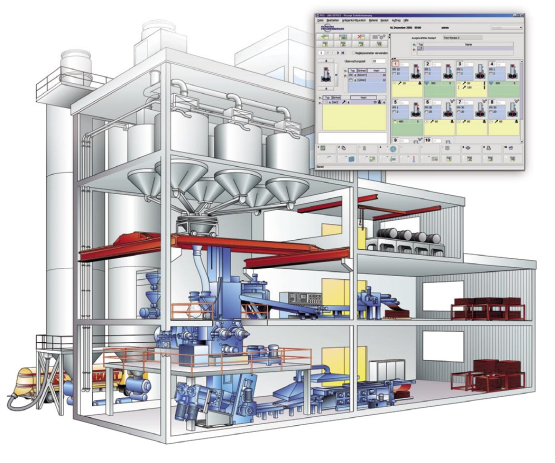

Ouli Machinery has released the latest generation of overall solution for the internal mixing workshop. This solution is based on the stability and reliability of the equipment, with the design concept of “One is enough”. Through intelligent upgrades, it solves the problem of equipment production that varies from person to person, helps customers increase the overall production efficiency by 10%, and continues to promote automation and automation in the rubber industry. Intelligent and information-based upgrades.

Based on thinking about the current situation of the industry and insights into the development trends of the mixing workshop, Ouli has built a strong research and development team of mixing equipment and a mature R&D and service system. It is a supplier of mixer workshop equipment and integrated solutions for mixers, batch off cooling, warehousing and logistics, and integrated software.

The new overall solution for the internal mixing workshop has four outstanding advantages.

First, the integrated mixing solution is more matur

After more than 30 years of continuous research and development, Ouli’s full range of internal mixing core equipment has continued to improve in terms of performance and stability; by providing end-to-end automation solutions for small materials, rubber blocks, and films, we help customers open up the connection between core equipment. The docking of logistics and automation further reduces labor and improves production efficiency; through the integrated management software of the mixing workshop, all-round data management and control is achieved, providing customers with comprehensive production information, simplifying workshop management, and realizing a transparent and digital mixing workshop .

Second, it is more intelligent and easier to operate.

With the goal of “one mixing line requires only one operator and one maintenance worker”, we have realized the same platform management of mixing product software, and reconstructed the relationship between people and equipment by creating intelligent operation and maintenance, intelligent production, and intelligent service scenarios. Let the device think, change people from active to passive, make people’s operations simple, improve customer experience, and solve the problem of device use that varies from person to person.

Third, the stability and reliability of the entire equipment continues to improve.

Digitizing and platforming design experience realizes the transformation of mixing engineering products from order-based design mode to configuration-based design mode, avoids the occurrence of repetitive design quality problems, and is the basic guarantee for equipment stability. Through equipment reliability system engineering, reliability design, data analysis and testing of parts and components are carried out to improve the reliability and stability of key products.

In terms of delivery, based on the integrated design of machinery, electricity, pneumatics and software, we realize the productization of complete sets. During the processing and assembly process, process control is carried out through standard specifications and special tooling, as well as in-factory assembly testing and inspection of module modules to ensure a 100% factory pass rate. Adopting the One Line Technology design concept, the suite only needs to be connected with one communication line and one power line, achieving high-quality and fast on-site delivery. The overall delivery efficiency is increased by more than 50% compared with the previous generation.

Fourth, strong overall solution delivery capabilities

Through modular and standardized methods, more than 30 years of material handling experience and more than 5,000 sets of equipment operating experience have been accumulated into a digital technology platform. With customer needs as the center, it continues to conduct research and development iterations throughout the product life cycle to ensure the quality of product delivery.

Ouli has established a complete project management system and achieved refined management in terms of project planning, risks, quality, changes, etc. We have professional domestic and overseas delivery teams and local processing and installation resources to ensure the implementation and delivery of overall overseas solutions. Relying on SoftControl’s global service system, localized services can be achieved and customers can be provided with 7*24-hour fast service.

As the leading professional supplier of “total solutions for mixing workshops” in the rubber industry, Ouli always focuses on customer needs, will continue to invest in automation, intelligence, and informatization, and will continue to launch high-quality products that meet the needs of future mixing workshops. Products and solutions help customers make perfect rubber for every vehicle, allowing the rubber industry to reach new heights in the world.

Post time: Nov-24-2023