Since the first programmable controller (PC) was introduced in the United States in 1969, it has been widely used in industrial control. In recent years, China has increasingly adopted PC control in the electrical control of process equipment in the petroleum, chemical, machinery, light industry, power generation, electronics, rubber, plastics processing industries, and has achieved remarkable results. Welcome to all industries. Our factory began to apply the programmable controller to the vulcanizing machine in 1988, and the use has been good. Take the OMRON C200H programmable controller as an example to discuss the application of PC in vulcanizer.

1 Features of C200H Programmable Controller

(1) The system is flexible.

(2) High reliability, strong anti-interference performance and good environmental adaptability.

(3) Strong function.

(4) The instructions are rich, fast, fast and easy to program.

(5) Strong fault diagnosis capability and self-diagnosis function.

(6) Diversified communication functions.

2 Advantages of using a programmable controller on a vulcanizer

(1) Simplified input devices and their own wiring, such as universal transfer switches, buttons, etc. can be simplified from a complex multi-group combination to a single group combination. The wiring of limit switches, buttons, etc. can be connected to only one set of contacts (normally open or normally closed), and the other state can be recognized internally by the PC, which greatly reduces the wiring name of the peripheral device.

(2) Replace the tilting wire of the relay with software. It is convenient to change the control requirements. The PC adopts a microcomputer-based electronic circuit, which is a combination of various electronic relays, timers and counters. The connection between them (ie internal wiring) is performed by the command programmer. If it is changed according to site requirements Control mode, modify the control circuit, just use the programmer to modify the instructions, it is very convenient.

(3) The use of semiconductor components to change the contact control of the relay to the non-contact control of the PC has greatly improved. J relies on the stability of the phase, and the failure of the relay of the original relay disc is controlled, such as the failure of the relay coil burnout, the coil sticking, the grid fitting is not tight, and the contact is off.

(4) Expansion I/0 Hunger has two power supply models: 1 use 100 ~ 120VAC or 200 ~ 240VAC power supply; 2 use 24VDC power supply. Input devices such as buttons, selector switches, travel switches, pressure regulators, etc. can be used as a signal source for 24VDC power supply, which can avoid short circuit of the switch, pressure regulator, etc. due to excessive temperature in the production environment, and improve the safety of maintenance workers. , reduced maintenance work. The output terminal can directly drive the output load of the solenoid valve and contactor through the 200-240VDC power supply.

(5) In addition to CPU error, battery error, scan time error, memory error, Hostink error, remote I/O error and other self-diagnosis functions and can judge the PC itself, it corresponds to every point of I / O There is a signal indicator that indicates the 0N/OFF status of I/0. According to the display of the I/O indicator, the fault of the PC peripheral device can be judged accurately and quickly.

(6) According to the control requirements, it is convenient to construct the most suitable system and to facilitate expansion. If the vulcanizer needs to add and improve the peripheral control system, add the expansion components on the main CPU, and the devices need to be networked later, which can easily form the system.

3 How to program the vulcanizer

(1) Confirm the actions that must be taken throughout the normal operation of the vulcanizer, and the relationship between them.

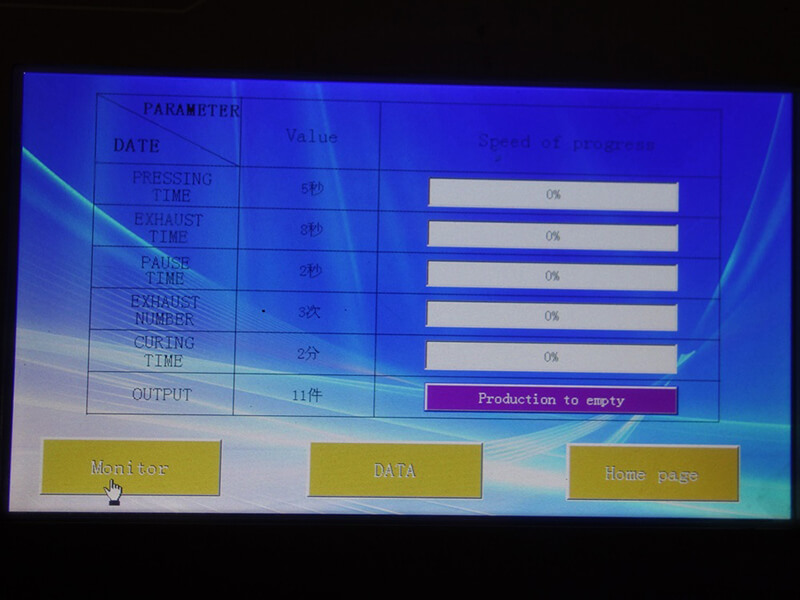

(2) Determine the number of input points required for the output switch to send the input signal to the input device of the PC; the solenoid valve, the contactor, etc. as the number of output points required to receive the output device from the PC output signal. Then assign an I/O bit to each input and output point while assigning an “Internal Relay” (IR) or a work bit and a timer/counter.

(3) Draw a ladder diagram according to the relationship between the output devices and the order (or time) in which the control object must be operated.

(4) If you use GPC (Graphics Programmer), FIT (Factory Intelligent Terminal) or LSS (IBMXTAT Programming Software) can directly edit the PC program with ladder logic, but if you use a normal programmer, you must convert the ladder diagram to help. A token (composed of address, instruction, and data).

(5) Use the programmer or GPC to check the program and correct the error, then test the program, and observe whether the operation of the vulcanizer is consistent with our requirements, and then modify the program until the program is perfect.

4 Common failures of vulcanizing machine automatic control system

The failure rate of the vulcanizer controlled by PC is quite low, and the failure generally occurs mainly in the following aspects.

(1) Input device

Like the stroke switch, button, and switch, after repeated actions, it will produce looseness, no reset, etc., and some may even be damaged.

(2) Output device

Due to environmental humidity and pipeline leakage, the solenoid valve is flooded, a short circuit occurs, and the solenoid valve is burned out. Signal lights are also often burnt out.

(3) PC

Due to the multiple short circuit of the output device, a high current is generated, which impacts the output relay inside the PC, and the output relay contacts are melted and stuck together, damaging the relay.

5 Maintenance and care

(1) When installing a PC, it must be kept away from the following environment: corrosive gases; drastic changes in temperature; direct sunlight; dust, salt and metal powder.

(2) Regular use must be checked regularly, as some consumables (such as insurance, relays and batteries) need to be replaced frequently.

(3) Each group of output units shall be output with 220VAC, and at least one 2A250VAC fuse shall be added. When the fuse is blown, it is necessary to check whether the output devices of the group are different. If you do not check and immediately replace the new insurance, it will easily damage the relay of the output unit.

(4) Pay attention to observe the battery alarm indicator. If the alarm light flashes, the battery must be replaced within one week (replace the battery within 5 minutes), and the average battery life is 5 years (below room temperature below 25 °C).

(5) When the CPU and the extended power supply are removed and repaired, the wiring must be connected when the wiring is installed. Otherwise, it is easy to burn out the CPU and expand the power supply.

Post time: Jan-02-2020